G & J Steel & Tubing uses many methods to cut metal tubing. The method of cutting depends on size, raw material coils or straight lengths, burr condition, and cut tolerance. Our main cutting process to begin the metal tube fabrication process is laser cutting. We use an IPG laser head fiber optics system. The use of cutting-edge laser technology allows our team to program the cutting of features and cut to length using solid model drawings to keep costs low and maximize project customizability.

TUBE LASER CUTTING

Not to be confused with sheet metal laser cutting, tube metal laser cutting relies on specialized machines to cut round, rectangular, square tube, and oval shapes or other structural profile shapes to specified lengths.

Typically, any feature or shape can be cut into the wall of the tube including slots, single wall or through holes, notches, or more complicated patterns. Tubing can be straight cut or miter cut, with all cutting burr free. The most common material includes:

- Carbon steel

- Stainless steel

- Aluminum

SIZE RANGES

We have two different laser cutting systems. The first is a fiber optics system with a size range of 7/8” ~ 7.00” OD with a maximum wall thickness of .236”. For smaller parts with OD’s down to .125” OD, we use a smaller CO2 laser system.

DESIGN SUGGESTION FOR ENGINEERS

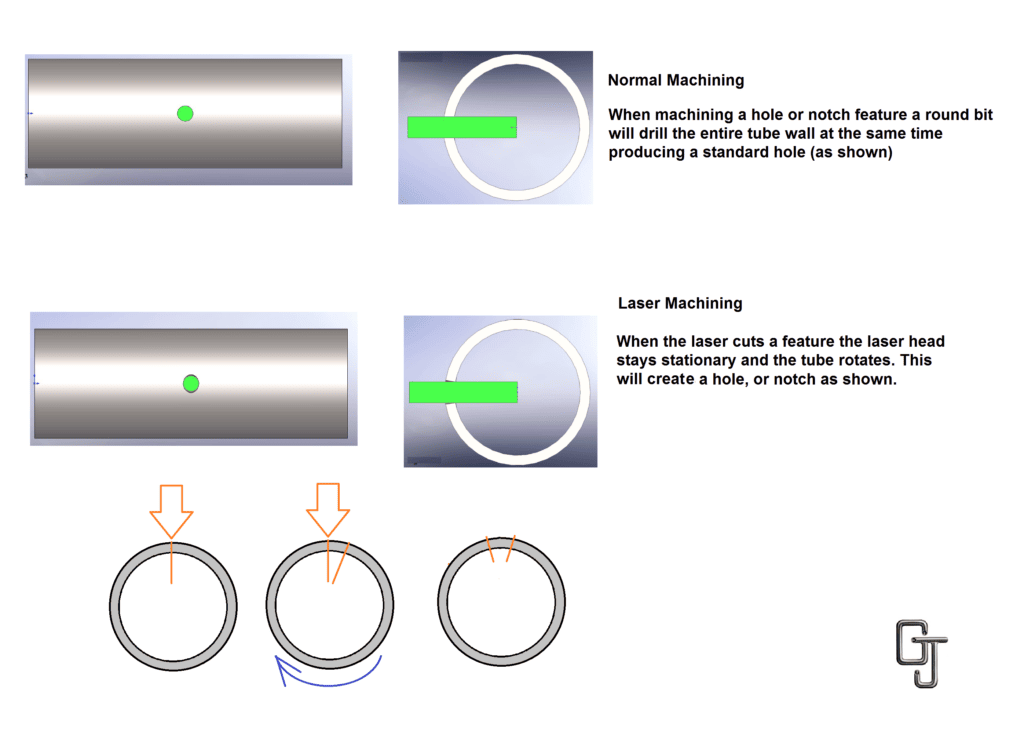

The laser system uses a lathe style gripping and feeding system with a laser mounted perpendicular to the tube. The tube advances and rotates under the laser head. Holes are produced by rotating the tube under the laser head. As such, the hole is not as square to the wall as it would be with a drill. Rather there might be a natural taper either from the OD to ID, or ID to OD as shown below.

G&J STEEL TUBE LASER CUTTING SERVICES

Our facilities can handle production runs requiring rates of anywhere from 60–1,000 pieces per hour. To ensure true end-to-end service, we limit our tube fabrication services to tubes ranging from .125” up to 7 inches OD.

We provide a full range of cutting capabilities, including:

- Laser

- Cold saw

- Electrolytic

- Shear-form

- Abrasive

- Screw machine

- Lathe cutting

- Rotary

Though each of these cutting methods has its place, laser cutting facilitates complex part geometries, no burr, no tooling and fast part turnarounds. When required, our team can also add holes or other complex cutout designs during the fabrication process. Thanks to the clean cuts provided by tube laser cutting, this method often requires no secondary machining or finishing operations.

G&J Steel and Tubing proudly services clients in numerous industries, including:

- Aerospace and aircraft

- Air compressors

- Air conditioners

- Automotive

- Beverage

- Electronics

- Engine

- Gas and appliance

- Heat exchange

- OEM

- Utility (power, sewer, water)

G&J STEEL: YOUR TUBE LASER CUTTING PARTNER

At G&J, our extensive service offerings and extensive industry knowledge make us the ideal tube laser cutting partner for your next project. As discussed, we can employ laser cutting services, and then complete your part to drawings by end forming, bending, coiling, and welding of fittings or brackets as required.

One of our team members will be happy to speak with you regarding your project. If you would like more information about our tube laser cutting capabilities or other metal tube fabrication services, please contact us.