TUBE BENDING SPECIFICATIONS

ROTARY DRAW SPECIFICATIONS

TUBE BENDING SERVICES

Tube bending uses metal-forming techniques to bend the material into precise layouts and shapes without crimping or weakening the metal. Most bending takes the form of elbow bends at different degrees or U-bends.

There are many types of tube bending methods for different materials, environments, and designs. G&J Steel & Tubing offers the following services:

COMPRESSION BENDING

In this technique, machinery bends tubing around a stationary bending die. Compression bending is faster and has a lower per-unit tooling cost than many other tube bending methods. However, it can’t be used for complex CNC tube bending designs or designs that require mandrels. It also has a relatively high labor cost on low-volume production runs, where the process will most likely be conducted manually.

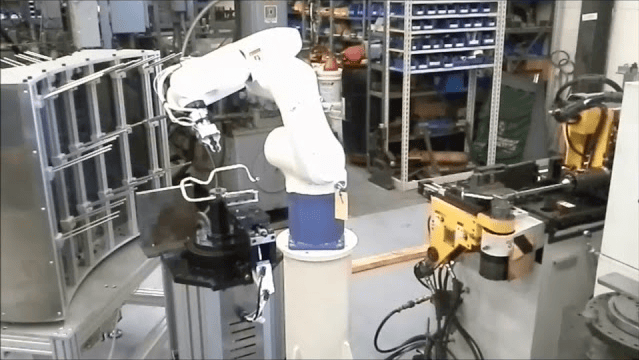

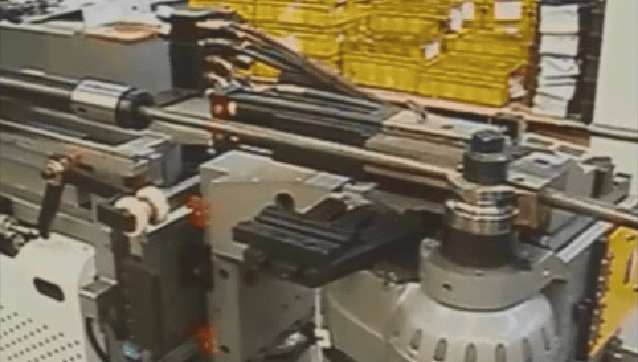

ROTARY DRAW BENDING

Unlike the stationary die used in compression bending, the rotary draw bending die moves to facilitate the bending process. The die uses CNC equipment to press itself against the tubing and then rotate the material into the required shape. This tube bending process can handle more complex designs and facilitates automated machining.

Other advantages of rotary draw bending include:

- Mandrels. Mandrels are inserts that stop tubes from crimping, wrinkling, or ovalizing during the tube bending process to preserve the integrity of the interior shape. Rotary draw bending can handle machining with tight CLR ratios, or bends with sharp angles. Specialty processes, such as split dies, can be customized to provide bends with an angle greater than 180°.

- Automation. Automated processes guarantee more consistent results for production runs that need to have identically shaped outputs from start to finish.

- More material options. Rotary draw bending uses CNC tube bending benders, which can apply enough force to bend denser or thicker material.

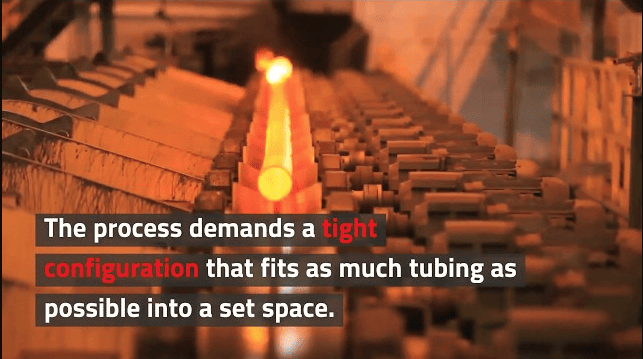

COILING

Coiling is a complex tube bending process because the tube needs to set against itself in a very precise layout to facilitate reliable heating or cooling operations. The process demands a tight configuration that fits as much tubing as possible into a set space.

G&J Steel & Tubing, Inc. uses several different processes, including manual coil machines, serpentine benders, and 6-axis CNC benders to create ideal configurations for different heat exchange applications.

Tube coiling is a specialized process for machining heating and cooling components and is considered to be a specialized form of tube bending.

COILING DESIGN

The engineers at G&J Steel & Tubing can help guide the design process for coil configurations. Some of the most important factors in creating coiling designs include:

- Degree of change during heat exchange from starting temperature to ending temperature

- Entry and exit points to finalize end forming and fittings

- Heating or cooling functions of the coil

- Pressure in the coil’s gas or liquid fluids

- Size and distance

- Space restrictions, which decide whether the coil will use serpentine, helical, or box coils

CUSTOM TUBE BENDING

G&J Steel & Tubing offers a wide range of possibilities for creating custom tube configurations. Our compression specifications allow for tubing materials of up to 2 inches in outside diameter (OD) and wall thicknesses from 0.01- 0.125 inches. The tubing material can also be from a wide range of commonly used metals and alloys.

Our standard tolerance is ±0.015 inches for compression processes and ±0.010 inches for rotary draw bending. Tighter tolerance levels are possible for custom tube bending projects, especially when utilizing CNC tube bending processes.

G&J’s team has years of custom tube bending and design experience, which means your custom projects will be expertly machined. All custom machining is handled in-house and uses tube CMM technology for quality assurance checks and final inspections. Our quality assurance policies also comply with ISO industry standards for reliable and replicable end products.

ENGINEERING TIPS FOR BENDING

- Center Line Radius (CLR) – Bends with a CLR to OD ratio of 2 to 1 or above can be used without a mandrel. For example, a 1” OD with a 2” CLR. Mandrel bending is required for CLR to OD ratios below 2 to 1, requiring higher labor costs and tooling charges. Try to avoid a 1 to 1 ratio as this requires even more expensive tooling and labor cost.

- Tangents – Avoid having tangents of one bend blending into the tangent of an adjacent bend. It is best to have a straight distance between bend tangents so the tubing can be gripped. When one tangent is close to another tangent, special grips are required to grip the tubing.

- Bend Stretch/Compression – Gripping and bending of tubing requires significant force. This will cause the wall to stretch and thin around the outside radii, and it will compress and thicken on the inside radii. The tighter the bend radii the greater this condition.

- Bends Near the End of the Part – Try to allow for some straight distance from the last bend to the end of the tube. This will allow for the material compression/stretch condition around the tube bend, causing the ends of the tube to become unsquare. If the straight is too close the last tangent trimming & deburring will be required which adds cost, time, and tooling.

- Spring Back– This is the condition in which metal wants to return to its original state or condition when bending force is applied. Spring back is a major consideration when selecting bend tolerance. To control this we must compensate by over-bending a few degrees. The harder the material the greater the spring back compensation factor required.

- Material Temper – When designing a bent tubular part consider using soft, or annealed, tempered material when possible. This helps reduce spring back, reduces stretch/compression, and prevents wrinkling or breakage.

CONTACT G & J STEEL TUBING, INC.

High-quality tube bending services create tubular configurations that are more reliable and longer-lasting. G&J Steel & Tubing machines tubes and heat exchange coils for industries including aerospace, automotive, utility, electronics, and more.

For more information about our tube bending services, please request a quote.

Contact Us