ENGINEERING

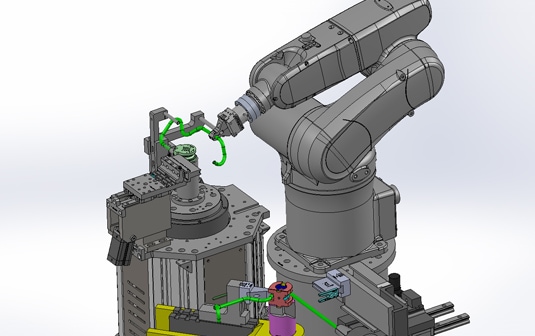

G & J Steel & Tubing, Inc. has in-house design capabilities if a customer wishes to upgrade a design, make a design more cost-effective or tailor a design to a specific application. We design and build all of our own tooling. We have also developed strategic partnerships with overseas machine shops to lower tooling cost when applicable. We are proficient with both AutoCAD and Solidworks but can accept a wide variety of image and CAD file formats.

G & J Steel & Tubing Inc. uses a Tube CMM (Coordinate Measuring Machine) on fabricated parts to ensure conformance to the acceptable tolerance. This machine is extremely accurate, and we use it to set up and adjust tube benders, reverse-engineer parts, or create a drawing if none exists.

QUALITY ASSURANCE

Our Quality Assurance system and policies are based upon ISO certification adapted to industry standards as set forth by the automotive, medical, and gas & appliance industries. We are experienced in PPAP lll sample submission including appropriate control and process plans, FMEA, flow charts and data. We perform in-process and final inspection using the latest Tube CMM technology providing X, Y, X coordinates.

We maintain SPC data on all manufacturing processes with capability ranging from 1.33 CPK to above 2.0 CPK on our various manufacturing methods.

SPECIFICATIONS

| Software | Solid modeling capability using Solidworks and AutoCAD | |

| Accepted File Formats |

|

|

| Capabilities |

|

|

| QA Equipment | Parts are measured with our Tube CMM Measuring and Bending System. We use it for bending set up, part programming for CNC equipment, inspection measurement for in-process, SPC, and final inspection. | |

| Compliances |

|

|

| Industries Served |

|

|