WELDING, GRINDING & POLISHING SPECIFICATIONS

TUBE WELDING, POLISHING, AND GRINDING

Welding is a critical process for fabricating useful and durable items from metal tubes. The welding process is used to join the tubing and create a variety of shapes and forms beyond the capabilities of tube bending. The welding methods we use at G&J Steel & Tubing include:

TIG WELDING

TIG welding is an electric, manual welding process that uses a non-consumable tungsten electrode to create a welding arc and an inert argon or helium gas to protect the electrode and weld from oxidation at the high temperatures produced by the welding torch. TIG welding may be performed with or without filler.

- TIG welding with filler is usually used when joining metal parts with thicknesses in the 2–5 mm range to increase the seal of the weld. Also known as homogenous welding, this method uses a filler metal to create the weld pool.

- TIG welding without filler, also called autogenous welding, does not use external filler since the base material itself serves as the filler material.

TIG welding may be used with a variety of metals and provides an accurate method for welding pipes and tubes. An experienced welder can avoid splatter and prevent the shards from the electrode that might weaken the weld.

MIG WELDING

MIG welding is primarily used by body shops and in manufacturing. Beneficial features of MIG welding include:

- Less waste. The continuous wire procedure used in MIG welding improves productivity and reduces scrap generation.

- Speed. MIG welding is faster than TIG welding. The process also features quick and easy cleanup since it generates no slag.

- Versatility. MIG allows welders to join metal tubes of very fine thicknesses.

Of note, MIG welding is more expensive than TIG welding. Also, joined materials must be cleaned of all contaminants or the weld might crack.

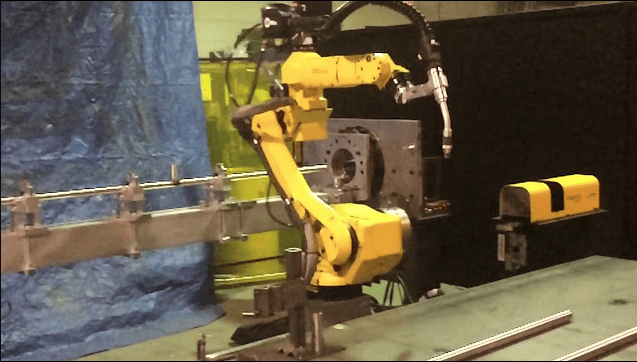

AUTOMATION OF WELDING

The key to cost containment of the welding process is to match the material, component design with equipment. The basic process is manual welding. For production, however, G & J can offer TIG and MIG:

- Robotic rotary welding that can perform 90-degree welds to secure brackets onto the end of a tube.

- Full automated X, Y, Z gantry robotic welder. There are two sides to the robotic gantry where we can tack weld on one side and motion control movement on the other to weld intricate tee joints.

- Orbital welding for straight butt joints.

BRAZING

Brazing is used to create a leak-tight joint using a soldering technique. The components must have a tight interference fit, they are cleaned, heated, and the soldiering material is introduced. The soldier is drawn into the joint by a principle known as capillary action. This technique is mainly a manual operation but can be automated using torches mounted to a turntable. Typically this is used to join dissimilar metals or including copper-based materials.

GRINDING

The purpose of weld grinding is to smooth, reduce the size, or shape the weld seam. The grinding process produces very fine finishes and achieves accurate dimensions within tight tolerances. Grinding uses an abrasive wheel as a cutting tool to grind away excess material. This process is especially suitable for hard materials in high-volume production operations. There are myriad grinding techniques, including:

- Centerless grinding

- Cylindrical grinding

- Electromechanical grinding

- Form grinding

- Internal grinding

- Pre-grinding

- Surface grinding

POLISHING

The polishing process helps to smooth out the surface of the tubing after welding & grinding is complete. Prior to polishing, the tubing must be thoroughly cleaned and sanded. It’s also important to select an appropriate polishing compound and buffing wheel to ensure a good result. There are many available grit belts and buffing wheels to achieve a variety of finishes. Their degree of polish is measured using a number or grit scale. The higher the grit finish the finer the grain structure. Typical industrial grit finishes are 120, 240, 320, and 600 grit finish.

AUTOMATION OF GRINDING AND POLISHING

Grinding and polishing tend to be labor-intense and thus expensive. To mitigate these costs G & J Steel & Tubing uses a variety of automated grinding and polishing methods. We use a long length polishing system, a system for radius bends, and robots programmed for specific component parts.

METAL TUBING FROM G&J STEEL & TUBING

G&J Steel & Tubing is a full-service metal tube fabricator. We can work with a broad range of metals and alloys, including:

- Aluminum

- Brass

- Carbon steel

- Copper and copper-nickel alloy

- Kovar

- Nickel and nickel alloys

- Rodar

- Stainless steel

- Titanium

We currently serve customers in a diverse array of manufacturing sectors, such as:

- Aerospace/aircraft

- Air compressors

- Air conditioning

- Automotive

- Electronics

- Engines

- Food and beverage

- Gas and appliances

- Heat exchanger

- OEM

- Utility (power, sewer, water)

G & J Steel & Tubing has extensive expertise fabricating metal tubing for a broad spectrum of industries and applications. Please contact us for any of your welding needs.