The term “automation” is often thought of as “using a robot to replace a manual operation”. However, this description is akin to describing heart surgery as just using a scalpel. When planning and establishing interconnected, automated fabrication operations, a collaboration between the facility’s engineering, quality, computer IT, and manufacturing departments is necessary to achieve a coordinated system.

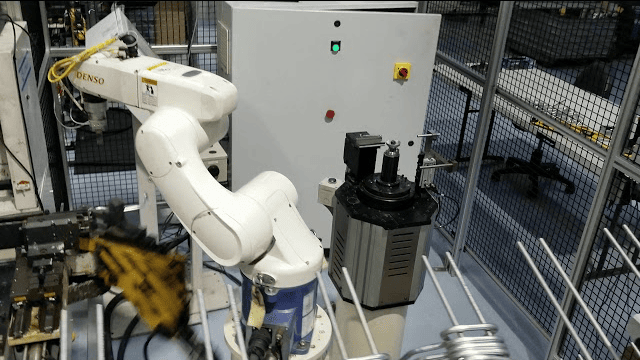

At G & J Steel & Tubing, we specialize in full-service metal tube fabrication solutions. For many of our work cells, we employ the use of robotic loading, conveying, and unloading equipment to automate operations, which allows us to increase processing capacities, improve repeatability, and reduce production costs.

FEATURES OF THE AUTOMATED WORK CELLS AT G & J STEEL & TUBING

Our automated work cells exhibit several unique features, including in regard to the following:

- Current equipment. We do not need to purchase expensive CNC equipment. Equipped with extensive engineering knowledge and skills, we can upgrade existing equipment to accommodate computer control inputs and produce outputs. The integration of programmable logic controls (PLCs) enables older units to act like newer CNC models. As a result, they can be integrated into the work cell chain quickly and easily, which saves time and money and maximizes flexibility.

- Building our own equipment. For certain fabrication operations, we can choose to build our own equipment. While we start from a common platform, we add multiple connected movements that replicate fabrication operations involving rotational force, linear force, turning force, pressing force, and the like.

- Part storage and loading. In part storage and loading operations, the use of robots is not as straightforward as it may seem. It can be highly challenging to design and build a loading system that allows each of a high volume of parts to be accessed by a robot. We have the engineering ability and experience to design and build our own loading system, complete with vision and sensing elements that present individual parts to the robots for processing.

- Part movement. In processing facilities, the most common robot form is programmed articulating robotic arms. They are widely available in the market, and their cost continues to drop. However, these units are not ideal for every application. Some applications require part movement involving individual X, Y, Z gantry systems. Our engineers can design and build these types as well.

- Vision inspection. For unattended (i.e., without a human operator) operations, it essential to integrate quality control directly into the work cell. If you are going to run parts for 24 hours, you must guarantee the pieces produced comply with customer requirements. Traditional inspection operations use Statistical Process Control (SPC), which statistically calculates the acceptability of a production lot. Combined with the use of a vision system, the technique can measure 100% of the parts, which guarantees 100% compliance. Our facility uses vision cameras and sensors during inspection operations.

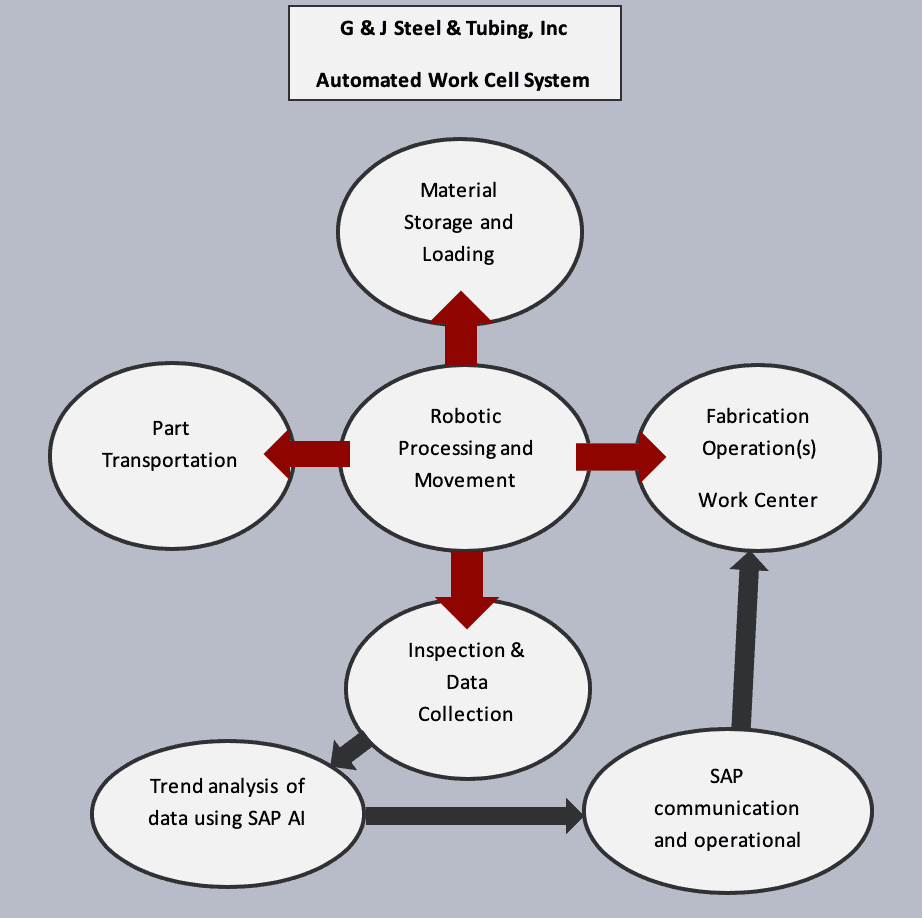

The diagram below illustrates our automated work cell system.

ADVANTAGES OF CONNECTED WORK CELL AUTOMATION

There are many advantages to connected work cell automation, including:

- Lower production costs. The main advantage is the elimination or reduction of direct labor cost.

- Better delivery consistency. Automation technologies reduce operational variability.

- Greater production capacity. The total annual production increases dramatically as 24-hour production operations become possible.

- Higher part and process quality. The use of visual inspection equipment results in overall better quality (near-perfect) parts. The inspection data can also be captured and shared to further improve on the production operations.

- Easier Continuous Process Improvements. Since data can be sent via Wi-Fi, we can monitor production data for trends using SAP Artificial Intelligence in real-time. The results of the analysis can then be used to identify any adjustments needed for the work centers to meet the required dimensional standards. Additionally, any other problems in the trend can be sent to key technical and manufacturing personnel.

- Broader flexibility. Rather than investing in new CNC equipment, we can upgrade our current equipment to connect with individual pieces of fabrication equipment. This ability allows us to reduce capital costs and maintain flexibility as work cells can be reconfigured with simple programming.

- Stronger control. We can accommodate all engineering requirements in-house, which allows us to control costs, lead times, and, most importantly, functionality. We can design into the work cell only what is required and can avoid purchasing unnecessary systems that equipment manufacturers want to sell.

For additional information about automated work cells or how we implement them in our facility, contact us today.