For this project, G&J Steel and Tubing developed an innovative set of processes to efficiently manufacture handrails to be used in a major mass transit system. Typically, railcars required 1.00-inch, 1.250-inch and 1.500-inch diameter-heavy wall stainless steel tubing; manufacturing these hand rails includes CNC tube bending, notching, welding, bracket & fitting assembly, grinding, and polishing. In order to achieve the desired surface finish, we had to develop multiple automated welding processes that would provide the quality and consistency that this project required.

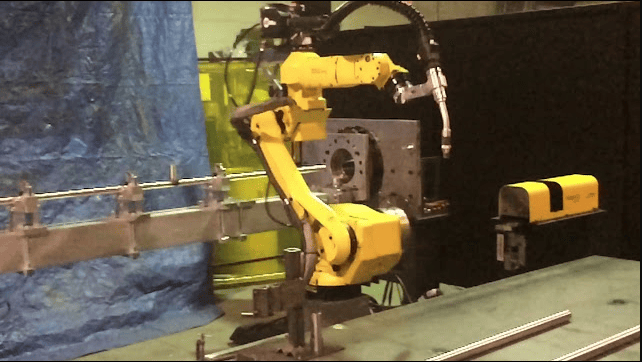

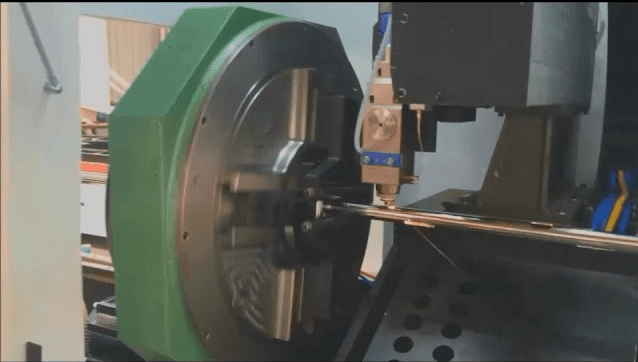

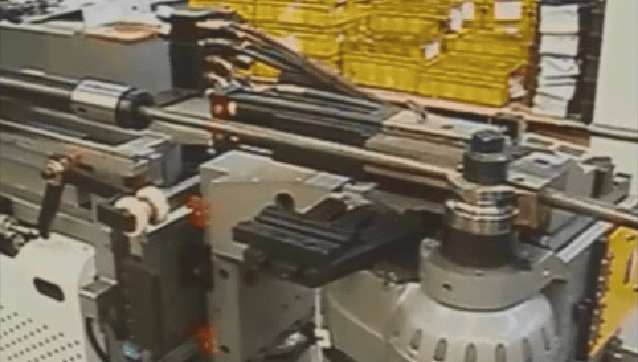

The handrail design called for the welding of brackets and notched joints, these would require the consistency and quality that only an automated solution could provide. To accommodate the bracket welding, we developed a rotary TIG welding system that delivered all the speed and consistency we needed to make production economical. To weld all of the notched joints, we built a fully automated, 5-axis robotic welder, with the ability to travel up to 18 feet. This further enhanced quality and repeatability.

These two systems create smooth consistent welds, but the surfaces had to be flawless. We had limited polishing expertise and we had to develop a procedure and process to match the unique finish per the engineering requirements. This initially required us to develop the formulation for the 240 grit belts required for the finish, then working with an equipment manufacturer a system was developed that would accommodate the many tight radii around all the brackets and notches. We even designed and fabricated check fixtures so the customers could perform final quality check on all the hand rails prior to installation. The results were repeat orders from this customer that continue today.

For more information please contact G & J Steel & Tubing directly.

Sustainability and Material Efficiency

This project emphasized durable materials and efficient manufacturing to support sustainability. Using heavy-wall stainless steel tubing guarantees long-lasting handrails, reducing replacement frequency. Precision CNC tube bending and automated welding minimized waste and rework. The polishing process was optimized to maintain strength while achieving the required finish. These efforts combined to deliver quality handrails with a reduced environmental footprint.

Why Choose G & J Steel for Transit Rail Projects

This case study highlights G&J Steel’s ability to handle complex transit handrail projects from start to finish. With fully integrated CNC tube bending, robotic welding, and polishing capabilities, the company maintained control over every stage of fabrication. This control translated into consistent quality, sustainability, and adherence to demanding schedules.

The successful delivery of subway handle handrails, which met precise engineering and finish specifications, led to repeat orders, demonstrating client confidence. G&J Steel’s experience producing both subway handles and bus grab handles makes the company a reliable partner for transit authorities and manufacturers seeking durable, compliant safety rails.

Get Your Quote on Durable Handrails

Transit authorities, vehicle manufacturers, and fabricators looking for dependable handrails are encouraged to contact G & J Steel. Whether you need custom subway handles, or durable bus grab handles, we can provide expert fabrication and finishing services to meet your project needs. Contact us today to discuss your requirements or request a quote for quality stainless steel tubing solutions.